The advantages of the biodesign technology

Many years of research and development of the product and the hundreds of public and private pools built worldwide have given us the opportunity to develop a technology with a low environmental impact, an extraordinary waterproofing quality and high structural performances thanks to the patented Biodesign coating. The technical sheets show that the waterproofing liners are superior to those used in traditional pools thanks to an elasticity of + 300%. Furthermore, they have a higher resistance against UV rays, ice, chemical products and a longer life.

Are you interested in a Biodesign Pool?

Do not wait any longer. Contact us now!

Technology

The Biodesign structural coating, consisting of resins specially created for this use and quartz sand, has a double mechanical resistance compared to structural concrete. In an absolute sense, these differences are already superior compared to the traditional construction methods. However, in order to understand their real value, they should be compared in their use: in fact, the Biodesign coating is not subjected to the stresses and the water pressure, because it is positioned on the waterproofing liner and submerged in the water.

Total customisation

The pool is tailor made, which increases the real value.

Certified structural solidity

This technology is particularly designed to remove the weaknesses of the old pools by redistributing the weight and improving the performances of the materials.

The best swimming experience

Swimming areas, beaches, seats and submerges walkways sculpted in natural stone offer the best swimming experience.

International patent protection

A true restriction of competition, which ensures stable margins for the whole network.

Ecofriendly building technology

Respect for the environment increases the value of the product and prolongs the success of the business.

Reduces installation times

The ease of management of the construction site and the reduced installation times help the organisation and the growth of our partners.

- Description of the structural application.

- The Biodesign technology.

- Analysis of the accidental loads.

- The Biodesign technology ensures a high level of safety towards the stresses caused by the ground and the water.

- Even in the event of settlements, there is no overload on the structure.

- The structural coating in quartz and resin is able to easily support the secondary loads.

- The mechanical properties of the Biodesign structural coating are very high.

- On the basis of the considerations of this study, there is no need for ordinary Biodesign projects to do further structural verifications.

Analysis of resistance and compression

UNIVERSITY OF MODENA AND REGGIO EMILIA

Engineering department “Enzo Ferrari”.

Are you interested in a Biodesign Pool?

Do not wait any longer. Contact us now!

Biodesign patent

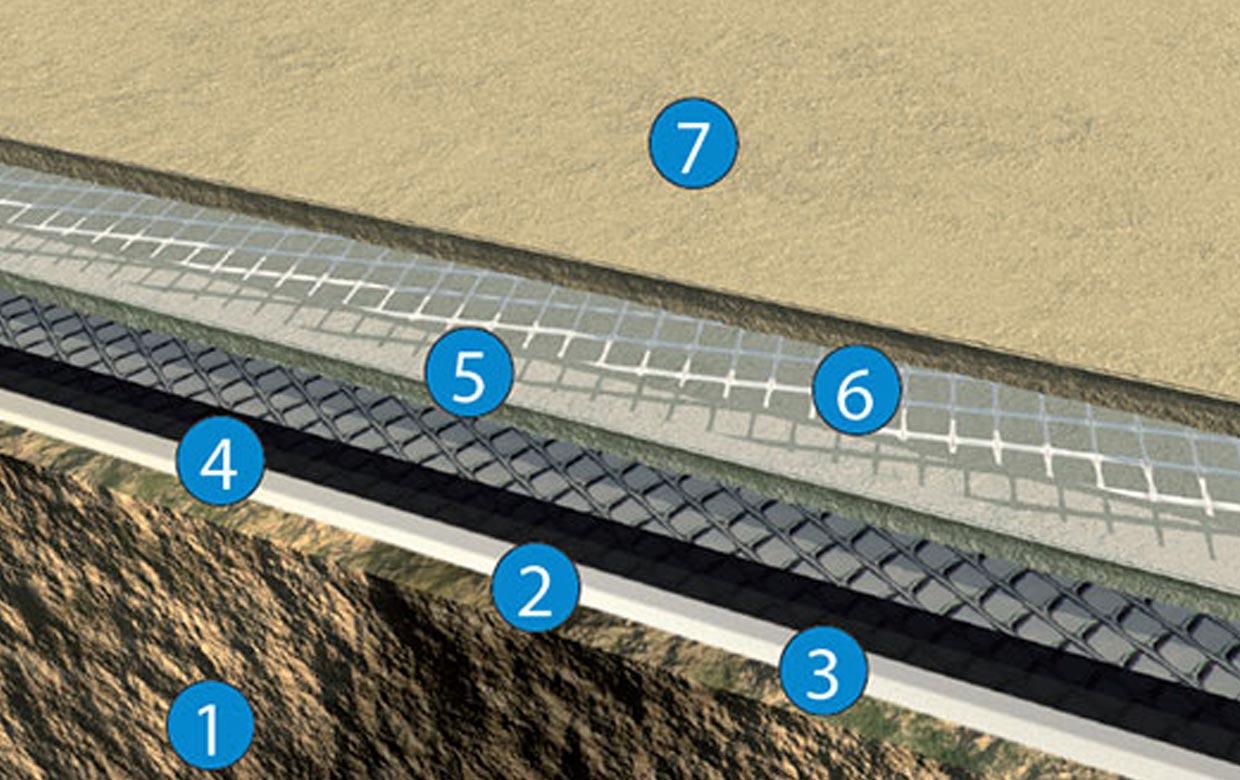

- 1 EXCAVATION

- 2 PROTECTIVE GEOTEXTILE

- 3 WATERPROOFING LINER

- 4 CONSOLIDATION NET

- 5 STRUCTURAL COATING FIRST LAYER

- 6 INTERMEDIATE CONSOLIDATION NET

- 7 STRUCTURAL COATING SECOND LAYER

A technology with low environmental impact, an extraordinary quality of waterproofing liner and structural performances of the patented Biodesign coating.

The technical sheets show that the waterproofing liners are superior to those used in traditional pools thanks to an elasticity of + 300%. Furthermore, they have a higher resistance against UV rays, ice, chemical products and a longer life..

The Biodesign structural coating, consisting of resins specially created for this use and quartz sand, has a double mechanical resistance compared to structural concrete.

Flexibility

The Biodesign technology uses a waterproofing liner in EPDM that is applied on the ground and protected by a special geotextile.

EPDM is a stable chemical material that is completely inert, it does not contain any polluting additives or heavy metals and does not free harmful substances in the environment. The old EPDM installation can be burnt in order to produce energy (provided that they do not emit any dioxins), it can be buried with domestic waste, or recycled for producing new products in EPDM.

Greenpeace suggests EPDM as an alternative to PVC.

Certification of the waterproofing liner

EPDM is a synthetic polymer that for more than 40 years has registered a continuous growth of its use in the automotive industry and civil engineering.

It is an elastomer, which is obtained from the copolymerization of ethylene, propylene and Diene Monomer that is vulcanised. The long plastic molecules are connected through crossed chemical bonds that build an elastic product, which is chemically stable with an unmatched resistance to UV rays, ozone, extreme temperatures and chemical substances.